Like a lot of people into making and electronics, I have huge number of parts. I do quite a bit of making at Robots and Dinosaurs, at home, and at occasionally at work, so I’m often travelling with parts to use during the day.

There’s another, very very large reason why I needed to get my organisation sorted, but I’ll cover that in later post.

Before I show what I ended up with, here’s some other strategies I’ve tried previously:

- Plastic drawer organisers: These are pretty awesome, but they’re also a fairly ‘fragile’ system. Knock it over, and you’ll be in trouble. Plus, you can’t take parts with you easily without transferring them to something else. If I’m asked for help, I like being able to say “No prob. I’ll just grab all my LEDs and meet you in 20 minutes” and figure out the details later. Plus, you have to figure out how much space to allocate to each thing, and it becomes a pain to maintain.

- Lots of little jars: More secure, portable, but much harder to keep organized. Also comes close to violating Adam’s ‘First order retrieveability’.

- Plastic tubs: I’m a big fan of using these for project stuff. All the parts related to a particular project go in the tub. I can grab it on the way out the door to the makerspace, I can pack stuff away, and know it’ll be ready to go next time. For raw components, though, it’s not so fun to dig through dozens of parts to find what you’re after.

Adam Savage is a good source on this, and he’s clearly spent a lot of time looking for good systems. If you haven’t seen it, check out his toolboxes and the a principle called ‘First Order Retrieveability‘. You shouldn’t have to move one thing to get to another.

The goal:

So, after chewing on organisation strategies for a couple of days, here’s what I came up with as a wishlist of features:

- First order retrieveability: For parts this is tricker than tools, since you’re probably going to have to open a box at some point. But it should be as easily as possible to look at what you’ve got, and get at your stuff. If I’m working on a project I’ll often pull out some boxes and spend a few minutes staring at, say, a bunch of switches and coloured lamps to try figure out an aesthetic that fits the project well. Make it easy to graze from your parts collection. You’ve worked hard to collect all those parts, you don’t want to realise weeks later you should have used that better widget, but it was over in another box you’d forgotten about. A good salad bar allows you to focus on the decision, not where you have to stand to see the food (all right, I’ll stop the metaphors now!)

- Must be easily extensible. No fixed drawers, locations, sizes. I don’t want to have to decide now the maximum of each type of part I’ll ever have for the rest of my life. If I’m donated parts (happens fairly frequently) I don’t want to turn things away because I’ve run out of little drawers on this side and it’d just ruin the aesthetic to put them somewhere else…

- Must be portable. Have to be able to at least grab a medium sized box/tub/etc and throw it in the car for a day’s hacking. Too large a ‘granularity’ is better than too small. Taking all the LEDs in a box is much easier than having to fish out individual LEDs, and then take the time to return them to their precise previous locations at the end of the day.

- Must be cheap(ish). No thousand dollar racks of custom fitted professional storage systems whose designers won style awards. I’m sure they’re lovely, but I try to do things that people just starting out in making can copy. Nothing says ‘barrier to entry’ like a big price tag.

- Must be invertable. Accidentally turning a box/tub/etc upside down, or tilting it when you’re carrying it is just going to happen. Having thousands of screws skitter across the floor, or cross-pollenate into other compartments isn’t acceptable.

With that in mind, here’s what I built in the last week. I was heavily inspired by Adam Savage’s parts rack, but I didn’t want to spend $3000+ on the Sortimo rack and cases.

The boxes:

I got a bunch of Tactix boxes from Bunnings for $12 ea. We use them in the makerspace for storing M3/M4/M5 screws and bolts, and they’re brilliant. The lids indent and grip the interior tubs to stop sliding, and when it’s closed you don’t get ‘cross pollination’ between compartments if you happen to invert the case. (I’m sure the proper Sortimo ones are better, but at $~60 a case it’s too rich for my blood. )

(Photo stolen from Bunnings, but hey, I like your stuff, ok?)

Also handy is being able to pull out a single tub from the case and take them to the bench while you’re working. If your collection grows, reorganising is just a matter of lifting and shuffling whole tubs around (Compare this to fixed ‘tackle boxes’, where reorganizing compartments can mean using tweezers to fish hundreds of tiny fittings out).

Another good trick I found is to cut the labels off packs and tape it to the drawer. Saves trying to identify the difference between a 12mm and 15mm screw by eyesight when you’re in a hurry, and when you run out you just stick the empty box in your bag and grab more next time you go past the hardware store.

The Rack:

The trays are awesome, I just needed a way to keep them organized. I wanted something simple, easy to transport inside the house, and as dense a storage as possible.

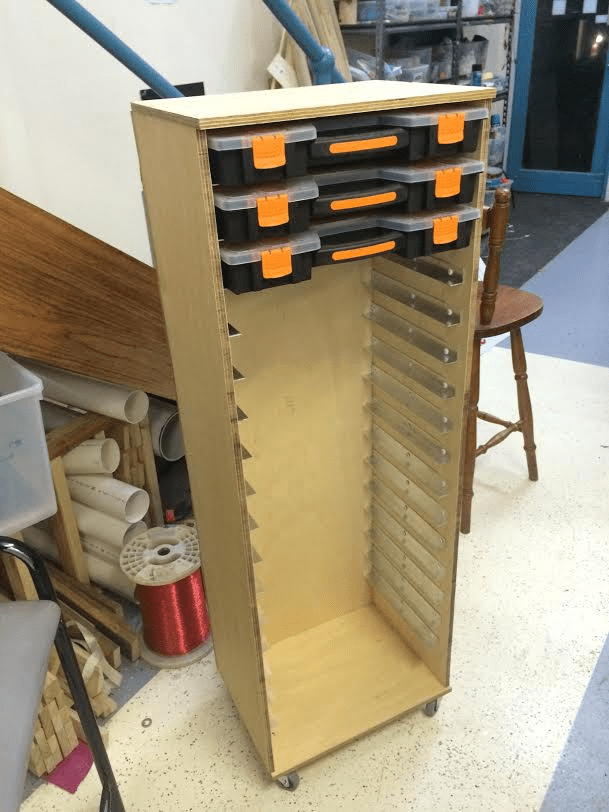

Here’s a pic of the just assembled rack, starting to test the fit:

and starting to get filled with cases. (Yes, my kitchen is messy, I was sorting 10 times my bodyweight in parts…)

and starting to get filled with cases. (Yes, my kitchen is messy, I was sorting 10 times my bodyweight in parts…)

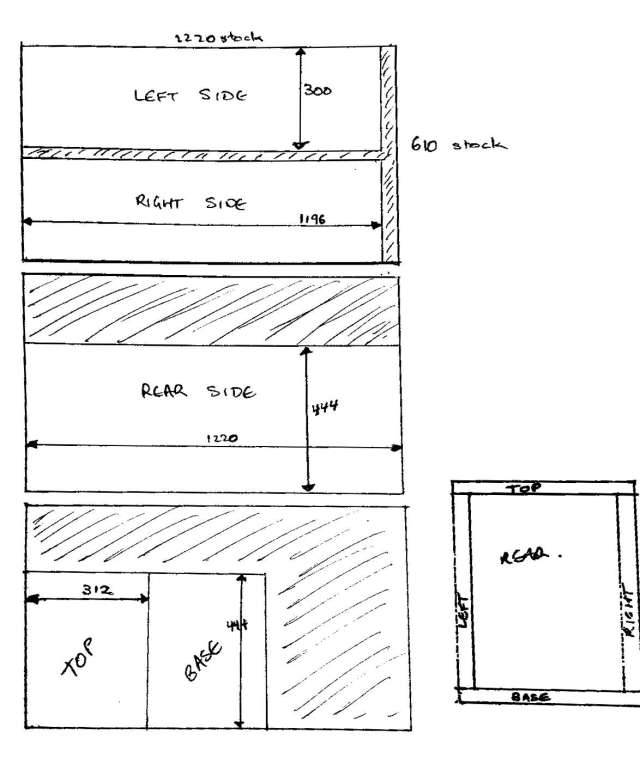

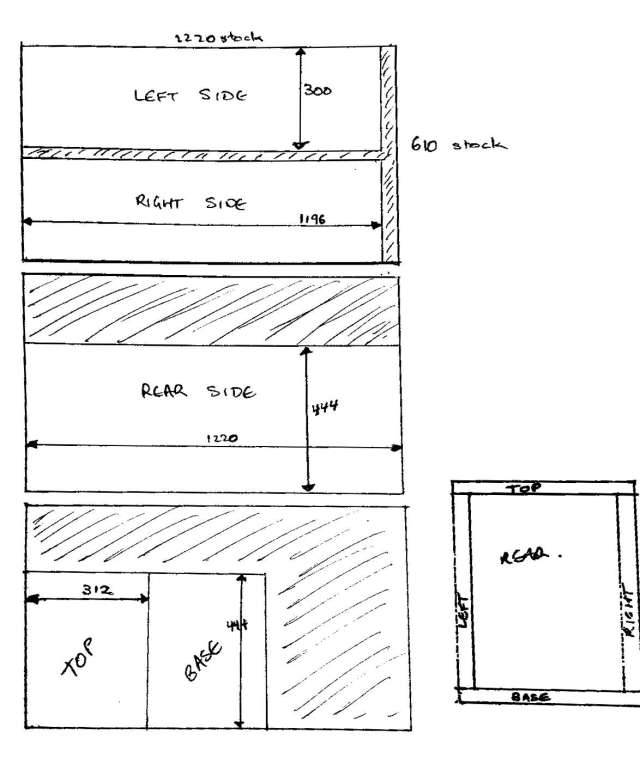

When it’s in place the wood top will be kept bare, so that you have a surface to rest cases on while you’re fishing around for parts. Here’s a quick sketch of the plans if anyone wants to make their own. It uses three sheets of 1220x610x12mm marine plywood, and makes a minimal number of cuts. 270mm x 25×25 ‘L’ extrusion is used for the rails, and is spaced every 70mm vertically for the smaller boxes. Some wheels on the bottom give portability.  Here’s the price breakdown per rack:

Here’s the price breakdown per rack:

| Plywood |

$ 88.14 |

| Castors |

$ 18.76 |

| Aluminium extrusion |

$ 55.20 |

| Screws |

$ 12.90 |

| Boxes |

$ 179.85 |

|

|

| Total |

$ 354.85 |

Not too bad, all things considered, and it should suit me for years to come.

Things still on the to-do list:

- Add better labelling, so you can read contents at a distance. Pretty sure the sticky labels from my label printer will wrap nicely on the handles here. Make the labels so categories are obvious e.g: ‘Screws – Self Tapping‘ and your brain can group them easily without thinking.

- Add reminders for unusual parts you want to try. Fairly often I’ll see or hear about a nifty tool or part (Forstener bit, nutserts, etc) I haven’t used before, but seem awesome. After getting some, I typically have to wait for it to come up in a project before I can use it. The danger is by the time it comes up, I’ve forgotten about it and will go back to the old method without thinking. I might add some gold stars or something to various drawers to remind me there’s something I’ve been meaning to try inside.

- Add some colour coding. All screws one colour, all electronics another colour, etc. You want to be able to know the ‘feel’ of where something belongs without having to think about it consciously.

- Better rack design that allows mixing of thick and thin boxes. I have a couple of ideas, but they’re a bit labour intensive without a big CNC router. I’d like to be able to mix thicknesses, because then all my parts can be in one spot, rather than having to be have some another rack based on height.

- Number each box. (Thanks Talsit!) Each box gets a number in permanant maker on the right hand side. (the red flip tabs label well). Makes it extremely easy to put things back in the right place, and if you want to reorder the system a squirt of isopropyl alcohol will remove the marker.

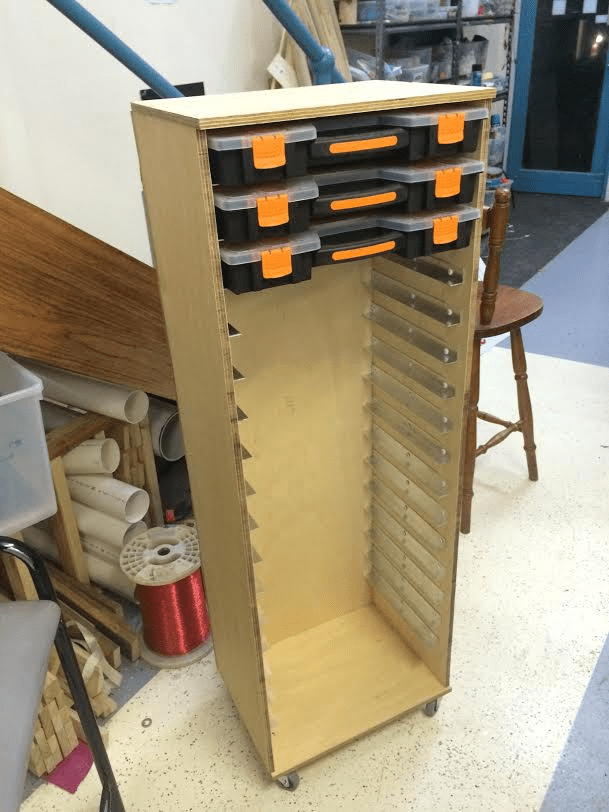

There’s obviously a bit of room for improvement. Organising the contents by colour and paint type (oil based, water based, etc). But the beauty of a rack is that it’s now pretty trivial to sort them out. I’ll leave the actual organising for someone else who’s less tired to do. 🙂

There’s obviously a bit of room for improvement. Organising the contents by colour and paint type (oil based, water based, etc). But the beauty of a rack is that it’s now pretty trivial to sort them out. I’ll leave the actual organising for someone else who’s less tired to do. 🙂